LED Light Guides...Guiding...Your way..........

| Home | Keypad Lighting | Front Lighting | Control Panel Lighting | MicroLens Arrays | Technology | Processing | About Us | Contact Us |

NEW Front Light Guides for E ink and Other Reflective Displays.........For Day/Night operation. |

|||||||||||||||||||||||||||||||||||||||

| Light Displays from the Frontside to Dramatically Lower Power Consumption. | |||||||||||||||||||||||||||||||||||||||

|

Front Light Guides are used with products from Watches to PDA's, E-readers, Phones and up to Outdoor Displays. They offer much lower power consumption than traditional backlighting of LCDs requires. Front light guides are clear plastic films that distribute the light from an array of edge lighting LEDs to the whole viewing surface of a display from the frontside. Traditional Back lighting of typical LCD displays is only 15% efficient or less. But, Front lighting a display with our technology is typically more than 80% efficient. So, there can be a dramatic savings in battery life of handhelds with displays using Front Light Guides. |

|||||||||||||||||||||||||||||||||||||||

New Nano-Imprinting Technology creates unique Light Guide Plates for Reflective Displays used in Portable Electronics |

|||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||

Benefits |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

Advantages |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

Complete Light Guide Assemblies are an option.... |

|||||||||||||||||||||||||||||||||||||||

|

We have the capability to provide complete solutions to your

lighting requirements. This includes the Light Guide,

Reflector, LED array or Light Bar, Cover Glass, Touch, Coatings

and Adhesives integrated into a complete assembly ready to

install in your application. Each assembly is designed to meet

your specifications. This assembly can include an LCD, Eink or

other type display with appropriate Front Lighting as

required. Sizes may range from a small Watch size up to large

32" display sizes. However, we can provide individual components such as Front Light Guides, Reflecors, LED arrays or Light Bars as required as well. |

|||||||||||||||||||||||||||||||||||||||

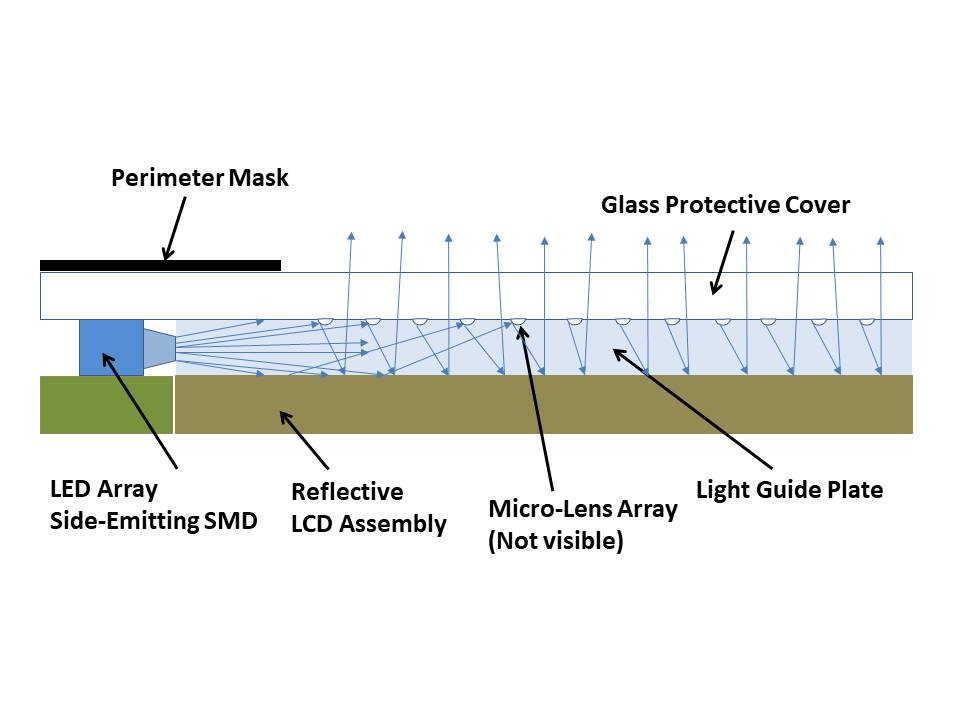

Front Light Guides : How they work |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

|

Light travels from the LED array on the left into the Front Light Guide Plate (FLGP) in blue. Internal reflection optical characteristics keep the light within the LGF. Only the local Micro-Lenses re-direct the light down to the LCD, E-ink or other type reflective display. Light, then is reflected by the LCD out towards the viewer. The density or fill factor of the Micro-Lenses can control the amount of light which is redirected. This allows the FLGP to provide uniform lighting across the display area. Also, it allows the use of fewer LEDs to provide uniform lighting to reflective displays saving power and cost. |

|||||||||||||||||||||||||||||||||||||||

Front Light Guide Plate Specifications |

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

| See MicroLens Technology | |||||||||||||||||||||||||||||||||||||||

| See Mastering and Manufacturing Processes | |||||||||||||||||||||||||||||||||||||||

| Home | Keypad Lighting | Front Lighting | Control Panel Lighting | MicroLens Arrays | Technology | Processing | About Us | Contact Us |

Google+

Google+

© 2009 Planetech International, LLC All rights reserved.