LED Light Guides...Guiding...Your way..........

| Home | Keypad Lighting | Front Lighting | Control Panel Lighting | MicroLens Arrays | Technology | Processing | About Us | Contact Us |

Light Guide Plates for LCD LED Backlighting

New Nano-Imprinted Thin Films Technology creates unique Light Guide Plates for Backlight Assemblies used in Portable Electronics. Below are examples of backlights customers have made using Nicrotek Light Guide Plates.

9.7"

| |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

Typical Backlight Film Stack |

|||||||||||||||||||||||||||||||||||||

| Front Protective Film | |||||||||||||||||||||||||||||||||||||

| Vertical Prism Film | |||||||||||||||||||||||||||||||||||||

| Horizontal Prism Film | |||||||||||||||||||||||||||||||||||||

| Diffuser Film | |||||||||||||||||||||||||||||||||||||

| Light Guide Plate / LED array | |||||||||||||||||||||||||||||||||||||

| Back Reflector Film | |||||||||||||||||||||||||||||||||||||

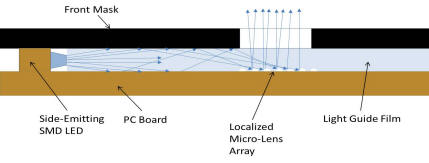

Light Guide Films: How they work. |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

The Nicrotek Light Guide Films (LGFs) are designed for effective use of LED edge light sources. Light from the LED sources is internally reflected down the length of LGF to the various viewing areas. The Localized Micro-Lens Arrays redirect light out of the film to the viewer only where it is needed (to each logo, image, key or button) by layout design. This new technology patterning allows light to be efficiently and uniformly directed where light is desired in a very low profile film. |

|||||||||||||||||||||||||||||||||||||

LCD LED Backlight: Light Guide Plate Specifications |

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

| See MicroLens Technology | |||||||||||||||||||||||||||||||||||||

| See Mastering and Manufacturing Processes | |||||||||||||||||||||||||||||||||||||

| Home | Keypad Lighting | Front Lighting | Control Panel Lighting | MicroLens Arrays | Technology | Processing | About Us | Contact Us |

Google+

Google+

© 2009 Planetech International, LLC All rights reserved.

8.4"

8.4"